THERMAL TREATMENTS

We operate heat treatments of carbon steels in general, alloy steels, stainless steels, aluminum. Treatment temperature up to 800 ° C effective, for higher temperatures a preliminary assessment is required

STRUCTURE

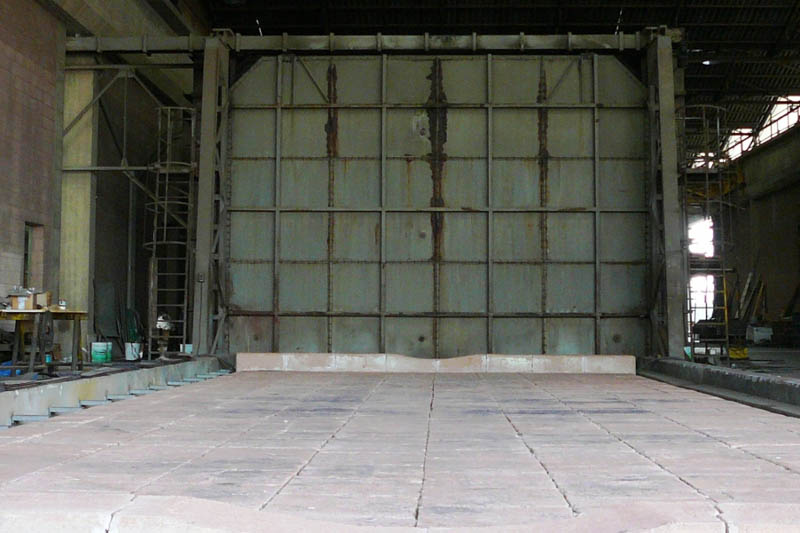

- Furnace with double cart with serviceable dimensions 6.5m x 5m x 17m.

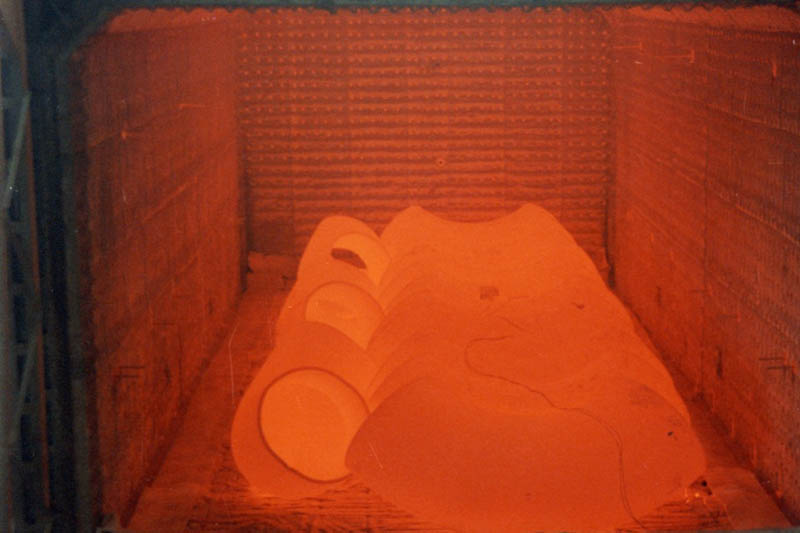

- 24 methane burners

- Series of thermocouples for electronically diagramming the temperature

- Automatic temperature control and regulation

On request, special welded thermocouples can be applied to the individual elements to be treated with a capacitive discharge welder for specific temperature detection in pre-established zones.

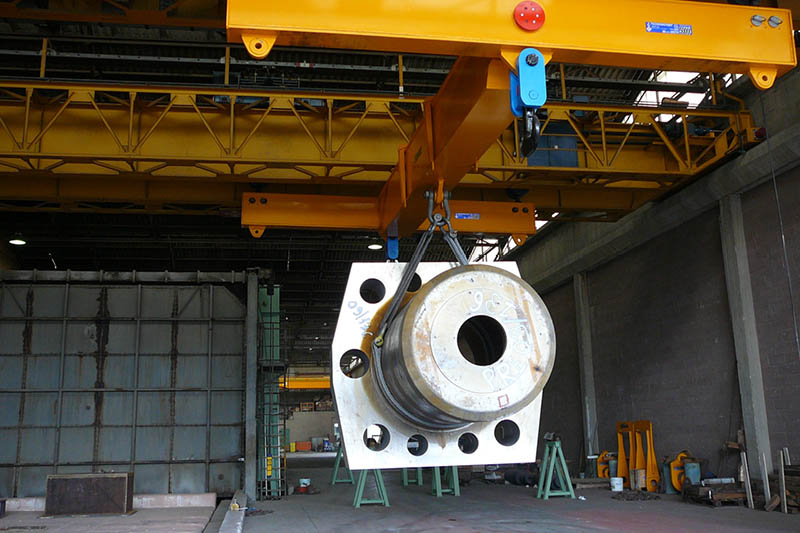

Single elements up to 200 tons can be placed in the furnace as well as multiple pieces with a total weight up to 200 tons, in fact, in support of the furnace there is an adequate lifting system consisting of a bridge crane and crane for large capacities.

APPLICATION SECTORS

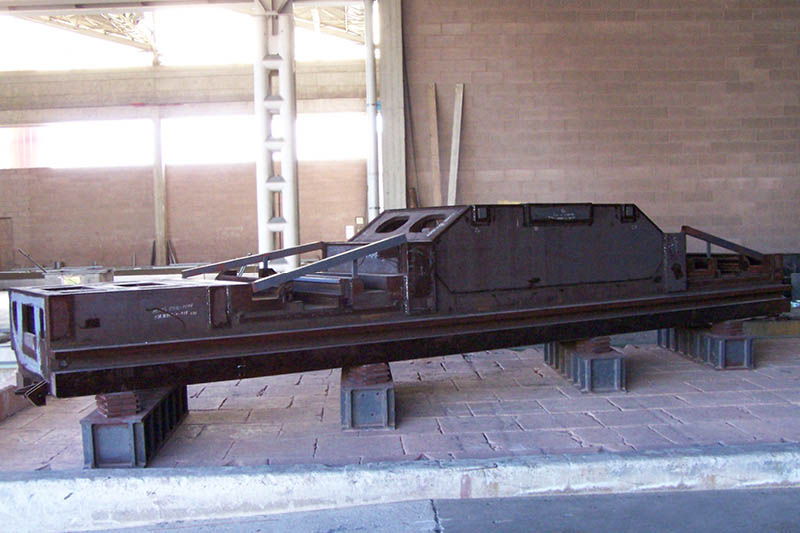

CARPENTRY

Heat treatments for carpentry: machine tools, presses

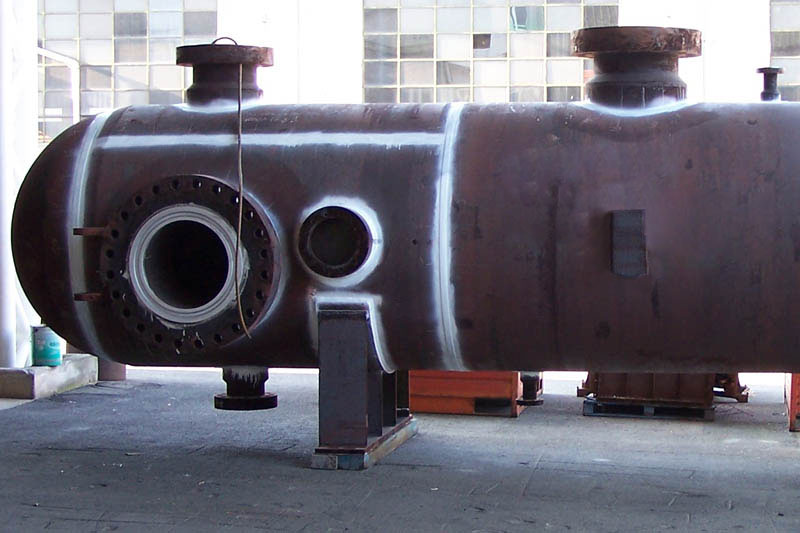

OIL & GAS

Heat treatments for Oil & Gas: heat exchangers, boilers, bundles, tubes, piping

BUILDINGS

Thermal treatments for buildings: tunnels, frames, beams

AERONAUTICS

Thermal treatments for the aeronautics sector: molds for fuselages

CHEMICAL INDUSTRY

Heat treatments for the chemical industry: pressure vessels, special INOX structures, piping

ALLUMINIUM

Aluminum heat treatments: stress relieve of finished products, homogenization of plates for cutting and extrusion

DOCUMENTATION

For each treatment, a certified copy of the time / temperature diagram is issued. On request, the certificate of the performed treatment is also produced and the evidence of internal procedures is provided