BLASTING

We operate automatic and manual blasting with metallic grit of carbon steel structures; manual sandblasting with quartz and river sand of INOX structures; sandblasting with corundum for the most delicate structures.

Sandblasting is necessary to remove the calamine from the pieces that have been heat treated; the cleaned parts can be mechanically worked without producing dust and clogging machine tools.

Sandblasting is also the fundamental operation in preparation for painting; the good quality of sandblasting is the basis for the durability of any painting or, in any case, the degree of blasting is defined by the painting cycle that will be applied.

Standard sandblasting has grade SA 2.5 as defined by ISO 8501-1, also known as near-white metal.

SETTORI DI APPLICAZIONE

CARPENTRY

Carpentry blasting for industry and buildings

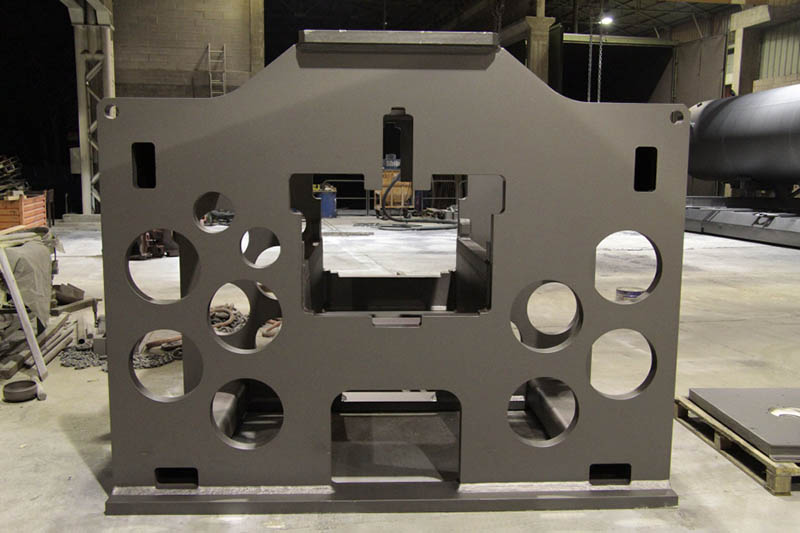

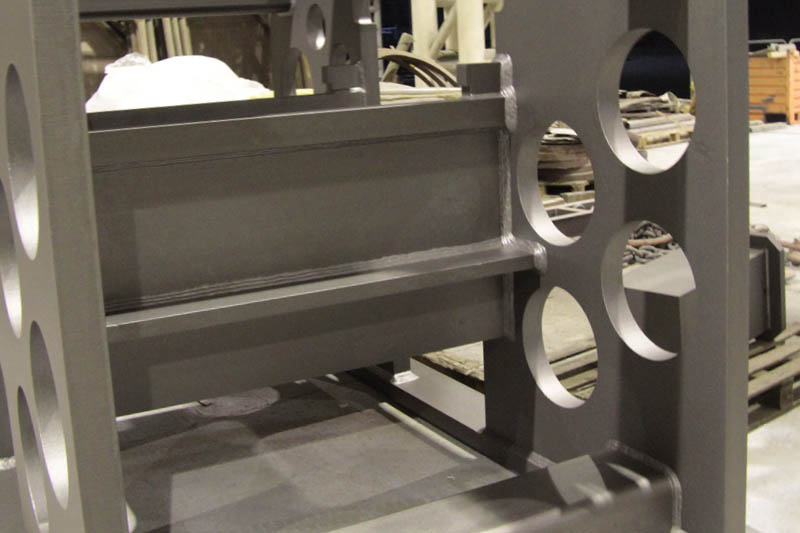

MACHINE TOOLS

Sandblasting of frames and machine tool structures

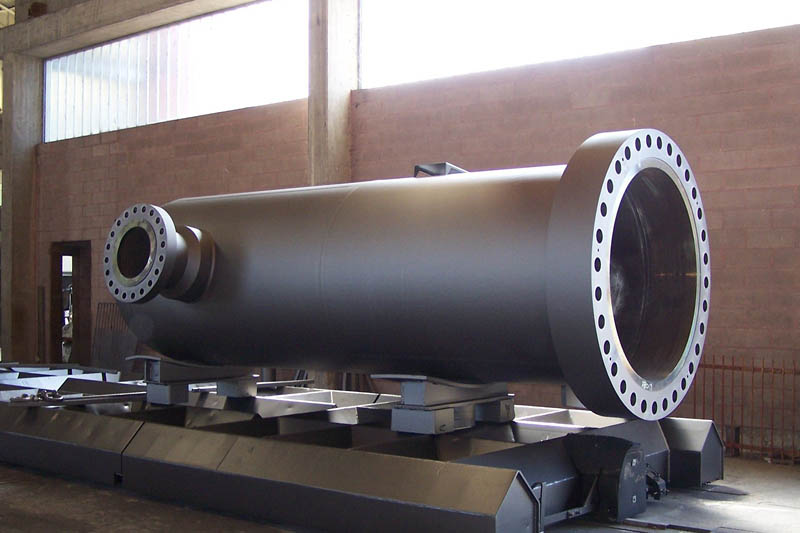

TANKS AND RECIPIENTS

Sandblasting of tanks, boilers and any cylindrical container

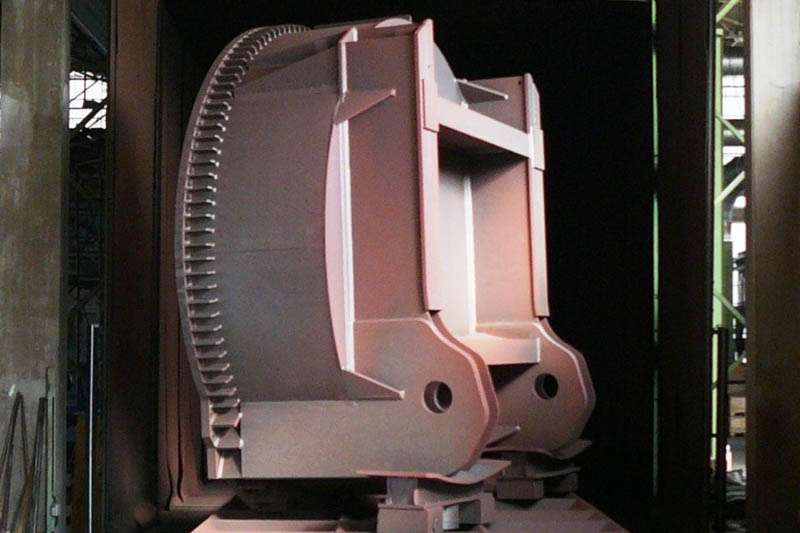

FURNACES AND STRUCTURES

Blasting of combustion furnaces and related loading / unloading structures

STRUTTURE DI SOLLEVAMENTO

Sabbiatura di strutture di sollevamento e movimentazione

LAMIERE

Sabbiatura di lamiere

STRUTTURE INOX

Sabbiatura di strutture INOX