PAINTING

We operate industrial spray painting with mixed air and airless with paints suitable for various applications.

Painting with epoxy primer is the classic and most requested operation to protect the structures after sandblasting for transport and during mechanical processing, but it is also the first layer of any painting cycle.

The most popular types of varnishes are: epoxy primer, zinc-based epoxy primer, inorganic zinc primer, epoxy enamel, polyurethane enamel, extra polyurethane enamel, silicon aluminum, acrylic aluminum; the enamels can be glossy, opaque, satin, peel.

We mainly use the paints produced by one of our partners for several years, but we can procure painting products from all the leading manufacturers.

Together with the customer, we evaluate the required painting specifications and set the activity from the “steel preparation” to the painting of the last coat and the final quality checks.

During the painting operations, it is possible to request the supervision of personnel certified by various certification bodies.

APPLICATION SECTORS

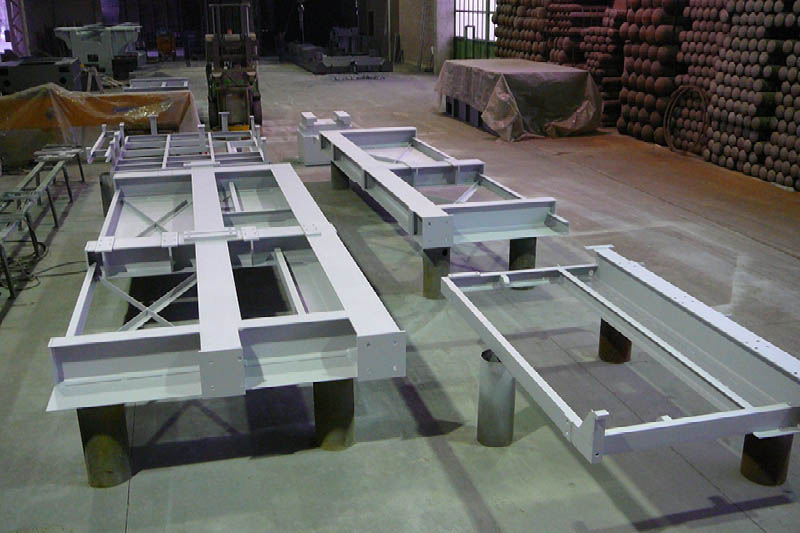

LIFTING STRUCTURES

Painting cycle complete with lifting and handling structures

COMBUSTION FURNACES

Complete painting cycle for combustion furnaces and related loading / unloading structures

CONTAINERS FOR CHEMICAL INDUSTRY

Complete painting cycle of containers for the chemical industry

STAINLESS STEEL STRUCTURES

Complete painting cycle for INOX structures

INDUSTRY AND CONSTRUCTION

Primer painting for industry and buildings

FRAMES AND MACHINE TOOLS

primer painting of frames and machine tool structures

TANKS AND CYLINDRICAL CONTAINERS

Primer painting or complete painting cycle for tanks, boilers and any cylindrical container